Introduction

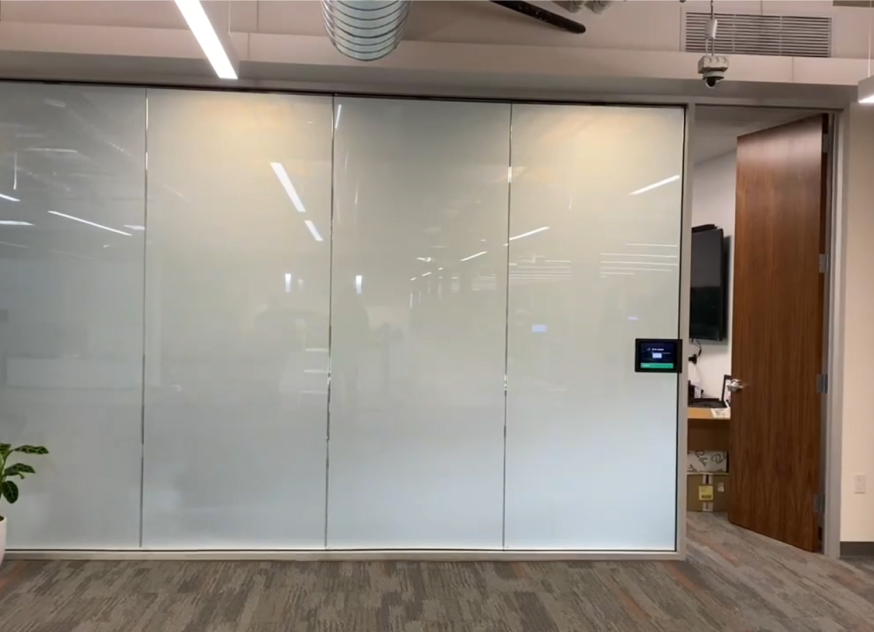

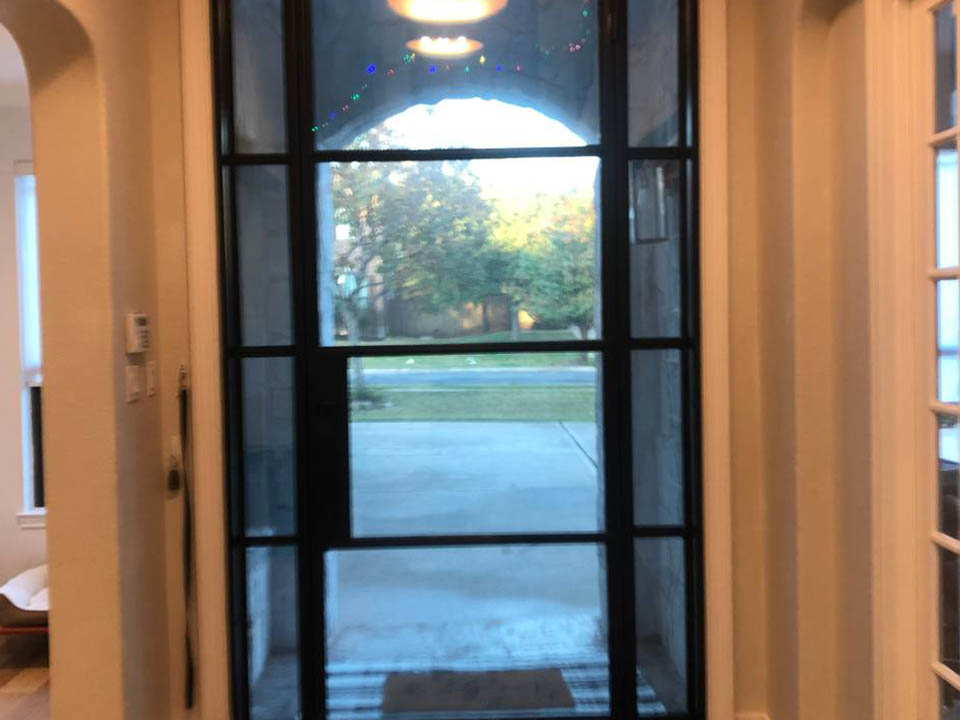

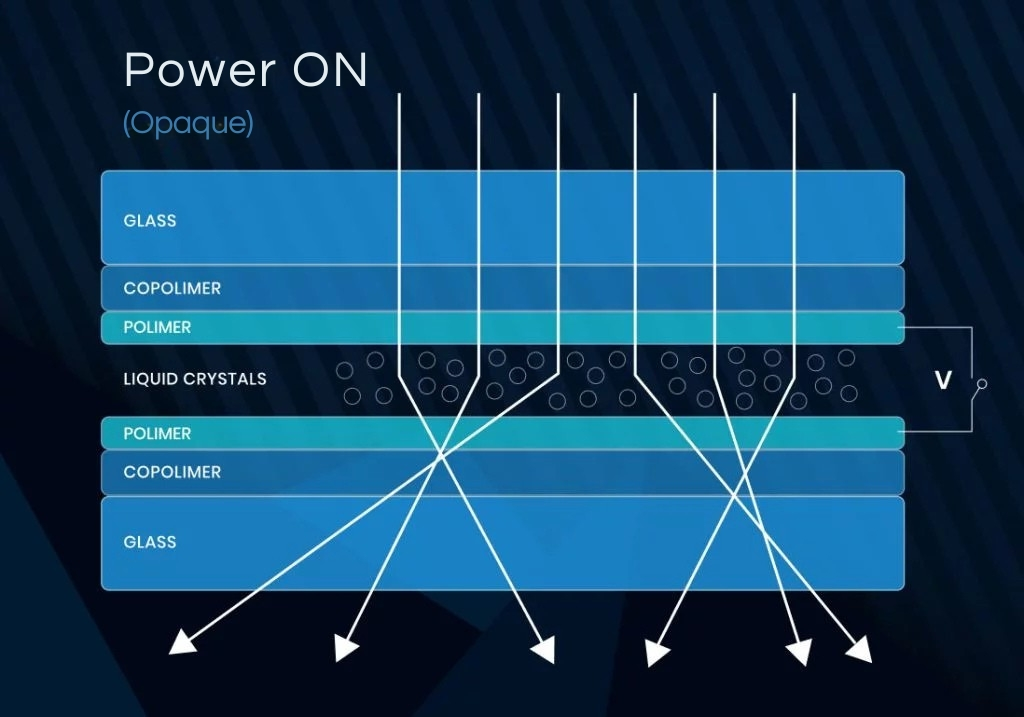

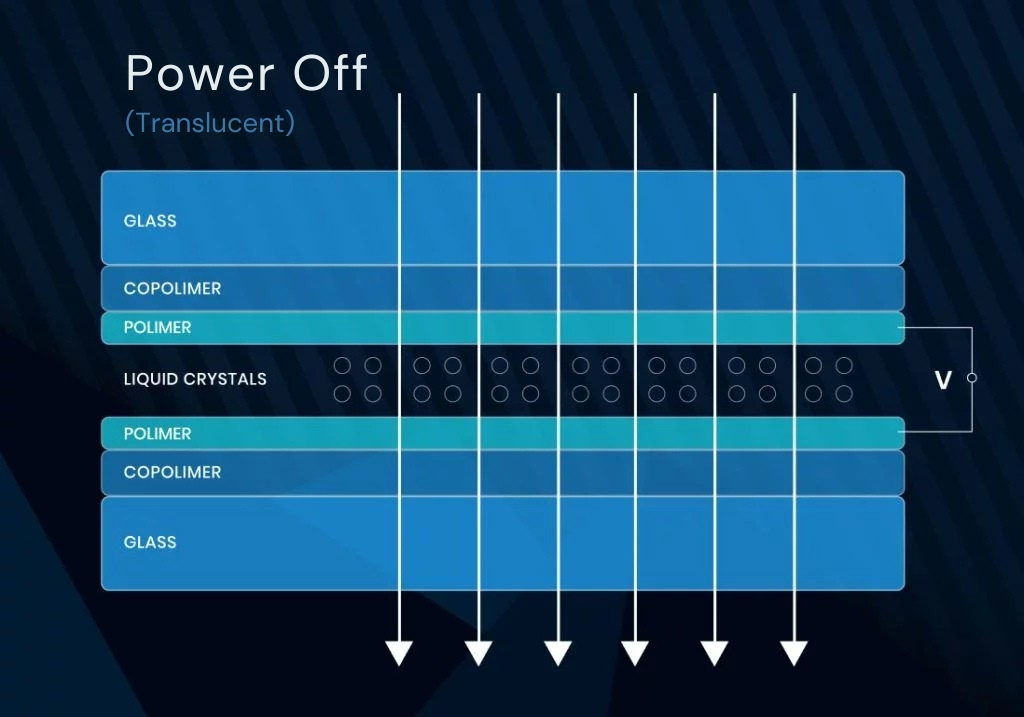

PriWatt® PNLC Smart Glass works on a simple principle: it turns opaque when power is on and clears when power is off. Stimulated with electrical current, liquid crystal molecules line up and incidental light passes through, creating opaque PriWatt Glass. When power is switched on, liquid crystals reorient themselves randomly, scattering light and the PriWatt Reverse Glass becomes opaque.

PriWatt® Reverse Glass Benefits

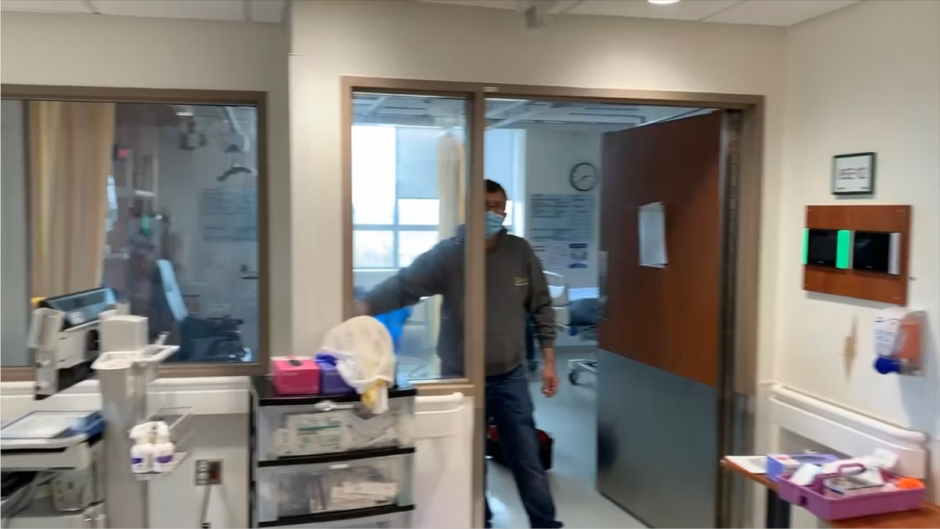

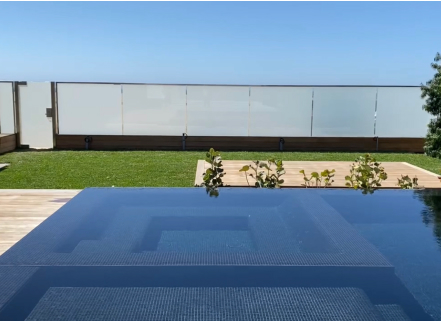

PNLC Smart Glass is also known as Reverse PDLC ( Polymer Network Liquid Crystals ) glass which makes it ideal for both residential and commercial settings, providing privacy and dynamic control over the transparency of glass surfaces.

PriWatt® Glass Applications

Electrical Parameters

- Working Voltage (ON): 24-80VAC

- Power Consumption <0.5W/SF

- Responding Time (OFF-ON): <200ms

- Responding Time (ON-OFF): <220ms

Optical Parameters

- Visible Light Transmission (OFF): 88%

- Visible Light Transmission (ON): 65%

- Haze (OFF): 3%

- Haze (ON): 95%

- UV Block: 99%

- View Angle (ON): 160°

Technical Specifications

- Max Size 57 inch x 150 inch

- Operating Temperature: -22℃ ~ 60℃

- Storage Temperature: 22-28℃

- Lifespan (ON): > 15 Years

Multitude of Control Options

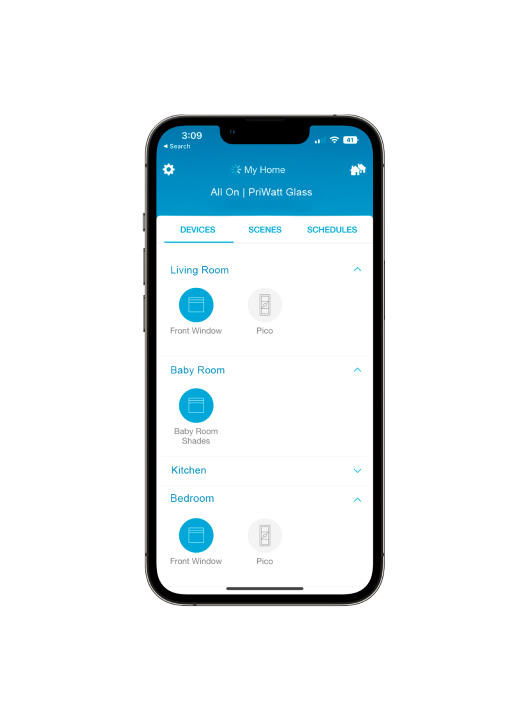

PriWatt™ Glass products can be controlled with a variety of devices and can be easily configured to work with your smart home through the z-wave technology.

SIMPLE SWITCH

Control your PriWatt® Glass Products with a simple light switch

DIMMER

A dimmer allows you to control the opacity of the PriWatt® Glass Products

SMARTPHONE

The PriWatt® Glass Products integrates with smartphones for convenient operation

REMOTE

The PriWatt® Glass Products integrates with a variety of remote controls

Z-WAVE

With Z-wave compatibility make the PriWatt® Glass Products a part of your smart home

AUTOMATION SYSTEMS

Testing, testing and some more testing.

To this day make-ups of PriWatt™ PDLC Technology have:

- Passed: ASTM E662 - STANDARD TEST METHOD FOR MEASUREMENT OF SMOKE OBSCURATION USING A CONICAL RADIANT SOURCE IN A SINGLE CLOSED CHAMBER, ON PRIWATT™ Interlayer

- Passed: ASTM E1354, STANDARD TEST METHOD FOR HEAT AND VISIBLE SMOKE RELEASE RATES FOR MATERIALS AND PRODUCTS USING AN OXYGEN CONSUMPTION CALORIMETER IN ACCIDENCE WITH NFPA 130 SECTION A.8.4.1.10, ON PRIWATT™ Interlaye

- Passed: BOMBARDIER SMP 800-C – TOXIC GAS GENERATION FROM MATERIAL COMBUSTION ON PRIWATT™ Interlayer

- Passed: ANSI/CAN 16 CFR 1201 Boiling Test

- Passed: ANSI/CAN IMPACT Test

Certified by UNDERWRITERS LABORATORIES : UL E514182

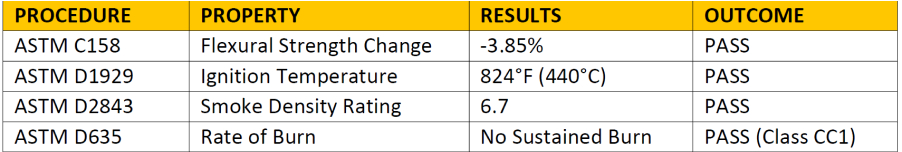

Modified EVA interlayer successfully passed all tests for Accelerated Weathering, Flexural Properties, Ignition Temperature, Smoke Density, and Rate of Burn in accordance with Miami Dade

US Patent # US11686966B2